The bioeconomy based on renewable natural resources has a long tradition in Lapland. In 2018, the output of Lapland’s entire bioeconomy sector was EUR 2.4 billion, of which the forest sector accounted for well over half. Other significant bioeconomy industries in Lapland include construction, the food sector, nature tourism and the energy and water industries.

In recent years, output linked to the bioeconomy has been growing in Lapland, even though the forest sector has declined slightly. However, the forest industry gained importance again when, in February 2021, Metsä Group announced that they would build a new EUR 1.6 billion bioproduct mill in Kemi.

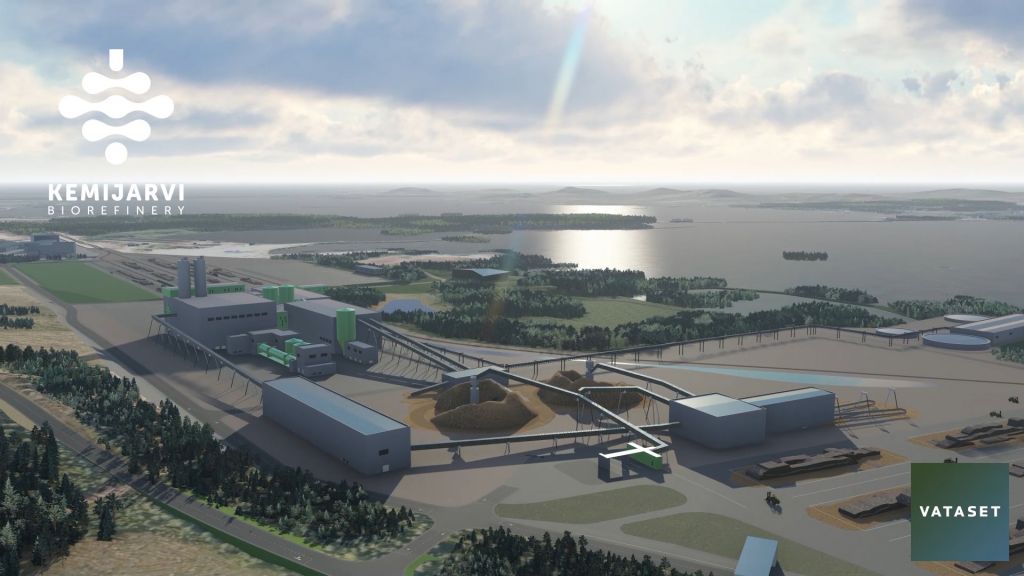

Also, just over 200 kilometres northeast of Kemi, in Kemijärvi, Vataset Teollisuus is currently mobilising funding for its EUR 1 billion bioproduct factory project before the investment decision.

It is therefore clear that the forest industry will continue to spearhead Lapland’s bioeconomy in the future.

Major investments underway in Kemi

The bioproduct mill of Metsä Fibre, which belongs to the Metsä Group, represents the largest national investment in the history of Finland’s forest industry. It is worth EUR 1.6 billion. Construction work is underway and the project is progressing on schedule. The new bioproduct mill in Kemi will be launched in the third quarter of 2023 and it will replace the company’s old pulp mill located in the same town. The new bioproduct mill in Kemi will secure all the 250 jobs that exist at the current pulp mill for decades to come and it will also create about 1,500 new jobs across its entire value chain in Finland, most of them in wood procurement.

– Demand for northern softwood pulp continues to grow globally. With our increased capacity, we are able to act as an ever-stronger partner and support the responsible growth of our clients. In addition, our new mill will be fossil-free and more environmentally friendly, says Ismo Nousiainen, CEO of Metsä Fibre.

Although demand for printing and writing paper in Europe and North America will continue to decline, according to Nousiainen, growth in the Chinese economy and e-commerce, for example, will increase demand for pulp-based products such as cardboard and tissue products. Completely new pulp-based products, such as textiles, are also creating new and exciting opportunities.

There is a plan to create an industrial ecosystem in connection with the bioproduct factory in Kemi, where several companies will be able to process the products and side-streams to develop and produce new commercially viable bioproducts.

– For example, at our Äänekoski bioproduct mill, our pulp is used to produce textile fibres and the crude methanol generated in pulp production is derived into biomethanol, which can be used as transport fuel, Nousiainen says.

In terms of logistics, Kemi is conveniently located at the back of the Gulf of Bothnia, which means that products can be shipped to all corners of the world more or less directly from the factory door.

New leaders of the Kemijärvi factory project

Vataset Teollisuus, which took the lead in the Kemijärvi biorefinery project in early 2021, has taken previous plans in an even more environmentally friendly direction. The environmental permit held by Vataset Teollisuus was confirmed by the Vaasa Administrative Court at the end of 2020, and construction is scheduled to begin in summer 2021. The new plant will be built in the immediate vicinity of Keitele Group’s sawmill and glulam factory in Kemijärvi.

Harri Vatanen, Managing Director of Vataset Teollisuus Ltd., says that all operations at the Kemijärvi factory are designed according to the principles of a circular economy, and the factory will utilise 100% of the wood. The Kemijärvi factory will produce high-quality long-fibre softwood pulp, soluble pulp and microcrystalline cellulose.

– In addition to our own pulp products, through our partners, we will utilise all the wood’s reusable materials in the cosmetics, food and pharmaceutical industries, for example, and we will also use the pulp to elaborate various bio-based products, says Vatanen.

The Vataset Teollisuus plant will employ 200 workers directly, and indirectly more than a thousand jobs will be created in the area. There is also a plan to create a bioeconomy cluster, Kemijärvi Biopuisto, in Kemijärvi.

– In addition to companies working in the industry, Kemijärvi Biopuisto will need various services, from maintenance to lunch services. The creation of new jobs in Eastern Lapland will lead to an increase in purchasing power, which will boost all sectors, Vatanen says.

In Kemijärvi, trains already run to the factory area, as wood is delivered by rail to the Keitele Group factory.

– Rail connections already exist and the airport is reasonably close. Of course, the infrastructure needs to be developed when it comes to transporting timber loads, for example.

Large projects such as the Kemijärvi plant could not progress without smooth cooperation with the municipalities and local authorities.

– The support of the City of Kemijärvi, Kemijärven Kehitys, and the locals is highly important. Our cooperation with the town council has been very smooth. This project is of primary importance to the region, Vatanen states.

Plenty of wood

When discussing bioproduct factory projects, there has been a lot of talk about the sufficiency of pulpwood. For example, Metsä Fibre’s annual demand for wood in Kemi will increase to 7.6 million cubic metres, which is 4.5 million more than currently. However, according to the company, there is enough wood available, and the wood rawmaterial will be imported to Kemi from Northern Ostrobothnia and Kainuu, as well as Sweden.

– All the wood we need is sourced from sustainably managed forests, mainly in Finland. At Metsä Group, we have an ecological sustainability program to help strengthen forest growth and carbon sequestration, safeguard the diversity of forest nature and improve water protection related to forestry, Nousiainen of Metsä Fibre states.

The biorefinery at Kemijärvi gets its wood within a radius of 150 kilometres from Kemijärvi.

– Kemijärvi’s location is ideal for a bioproduct factory, as it is surrounded by forests filled with top-quality northern wood. At present, the area should be thinned more than three times the current amount and the tending of seedling stands should be increased fourfold. According to Harri Vatanen, in the last ten years, over 120 million cubic meters of wood have grown in Lapland.